Most of us don’t have a 1,500 sq ft detached workshop with 12-foot ceilings, perfect lighting, and dedicated machine zones.

Most of us have:

- A garage bay we still park in.

- A basement corner.

- A shared workspace.

- Or a shop that already feels “full.”

And yet… we still want to cut full 4×8 sheets.

Cabinet parts. Wall art. Large signs. Templates. Production runs.

That tension — big capability vs small space — is exactly where the MakerMade CNC enters the conversation.

You can check it out here:

👉 https://laticy.com/CNC/Makermade

But before you click away and start pricing it out, let’s slow down and talk through what this machine actually is, who it’s for, and whether it makes sense for your shop.

Because this machine solves a very specific problem.

And it introduces a few trade-offs along the way.

What Is the MakerMade CNC?

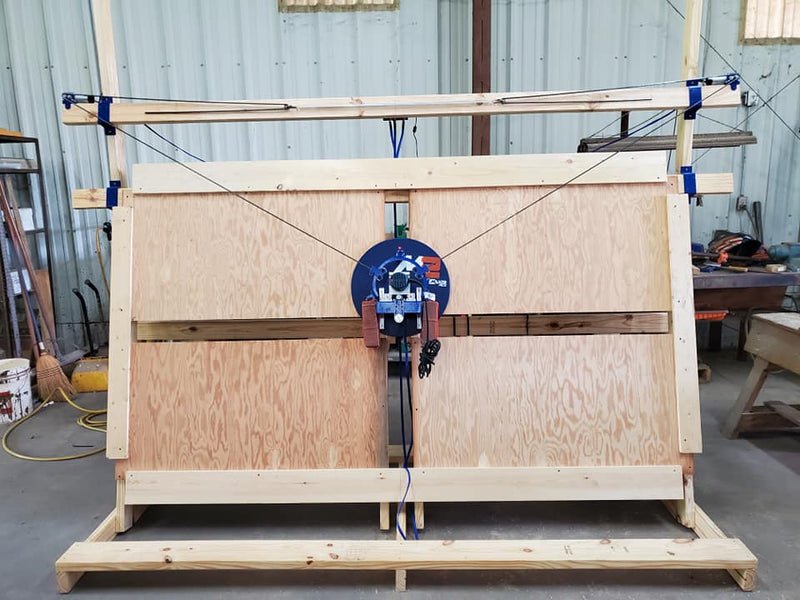

The MakerMade M2 is a large-format CNC system designed to cut full 4’x8’ sheets, but instead of using a traditional horizontal table layout, it mounts vertically against a wall or frame.

That’s the defining feature.

Instead of dedicating 4×8 feet of floor space (plus clearance), you dedicate wall space.

That changes everything.

Most traditional 4×8 CNC routers:

- Sit on a heavy welded frame

- Weigh hundreds of pounds

- Require full perimeter access

- Permanently own the center of your shop

MakerMade flips that idea.

It says:

What if we let gravity help us?

What if we lean the sheet upright?

What if the machine moves vertically instead of across a giant table?

It’s a very “maker” way of solving a space constraint.

And for the right person, it’s brilliant.

The Problem This Machine Is Trying to Solve

Before we talk specs, let’s talk reality.

If you want to process full sheet goods traditionally, your options are:

- Buy a 4×8 CNC table (expensive, huge footprint)

- Use a track saw and templates (manual, slower, limited repeatability)

- Pay someone else to cut sheets for you

- Break sheets down manually before using a smaller CNC

Each option has tradeoffs.

What MakerMade is trying to do is create an accessible entry into large-format CNC work without the massive infrastructure cost.

It’s not trying to compete with a $25,000 production router.

It’s trying to give serious hobbyists and small business owners a way into big-sheet capability.

That context matters.

Core Specifications (The Stuff That Actually Matters)

Let’s skip marketing fluff and focus on what impacts real-world use.

Cutting Area:

4 ft x 8 ft (full sheet capability)

Z Travel:

Approximately 3.8 inches

Max Speed:

Up to around 40 inches per minute

Materials (listed as compatible):

- Plywood

- MDF

- Hardwoods

- Laminates

- Plastics

- Thin aluminum sheet

Accuracy Expectations:

Many users report around ~1mm when dialed in properly.

Now — let’s interpret that like a shop owner.

1mm is absolutely usable for:

- Cabinet carcass parts

- Sign blanks

- Templates

- Wall art

- Decorative panels

Is it aerospace precision?

No.

But that’s not what this machine is built for.

Who This Machine Is REALLY For

I want to be extremely clear here.

This machine is not for everyone.

It shines for a specific type of person:

1. The Space-Constrained Builder

You want full-sheet capability…

But you don’t have space for a full 4×8 table.

This is the primary audience.

2. The DIY Mindset Maker

You enjoy building.

You don’t mind tuning.

You like understanding how your machine works.

This is not an appliance.

It’s a machine you build and dial in.

3. The Growth-Oriented Hobbyist

You’ve outgrown a small desktop CNC.

You’re starting to think about cabinet work.

You’re producing larger signage.

You’re scaling up.

But you’re not ready to invest five figures into industrial equipment.

That’s the sweet spot.

Who Should Probably Look Elsewhere

Equally important.

You might want to reconsider if:

- You want plug-and-play production.

- You hate calibration and tweaking.

- You expect perfect repeatability without maintenance.

- You’re running a high-volume cabinet shop.

This machine rewards patience and understanding.

If you want “turn key and go,” there are better (and much more expensive) options.

Vertical vs Horizontal CNC: What Changes?

This is where things get interesting.

Let’s compare.

Floor Space

Traditional 4×8:

- 4×8 footprint minimum

- Often needs walk-around clearance

- Realistically takes 6×10 feet or more

MakerMade:

- Uses wall space

- Frees up floor area

- Leaves central shop layout more flexible

If you’re in a garage shop, that’s a big deal.

Material Handling

Traditional CNC:

- Lift sheet onto table

- Secure flat

- Cut

MakerMade:

- Position sheet vertically

- Secure to frame

- Cut

Some people prefer one.

Some prefer the other.

There’s no universal winner.

Workflow Differences

With vertical orientation:

- Dust falls differently

- Clamping strategy differs

- Access to sheet edges changes

None of these are dealbreakers.

But they are different.

And you should go into it knowing that.

Real-World Pros

Let’s go deeper than a bullet list.

1. Massive Capability in a Small Footprint

This is the headline feature.

You get 4×8 capability without 4×8 floor commitment.

For many makers, that alone justifies the machine.

2. Affordable Entry into Large Format CNC

Compared to industrial 4×8 routers, this is dramatically more accessible.

It opens doors for:

- Small Etsy businesses

- Sign shops

- Cabinet hobbyists

- Side hustlers

3. Community & DIY Flexibility

Because of its design philosophy, it attracts tinkerers.

That means:

- Community tweaks

- Mods

- Setup improvements

- Shared learning

If you like that culture, you’ll feel at home.

Real-World Cons

Let’s be honest here.

1. Calibration Matters — A Lot

This is not “bolt it together and perfection happens.”

Tension, alignment, squareness — it all affects output.

If you rush setup, you’ll fight results.

If you’re methodical, you’ll be happier.

2. Accuracy Depends on Setup

Expect around 1mm when dialed in.

That’s good — but it requires care.

3. It’s Slower Than Industrial Systems

Max speeds are modest.

If you’re cutting production cabinets daily, speed may frustrate you.

For weekend or small-batch production?

Totally workable.

Router & Bit Considerations (Don’t Skip This Section)

Your results will depend heavily on:

- Router quality

- Bit sharpness

- Feed rate choices

- Material type

Even the best CNC in the world produces poor results with dull bits.

Budget for quality tooling.

That investment matters more than most beginners realize.

What Projects Is This Machine Best At?

Let’s talk practical.

Great use cases:

- Cabinet panels

- Shop furniture

- Large decorative signs

- Wall art

- Templates and jigs

- Furniture parts

- Built-ins

Less ideal for:

- Micro-detail engraving

- High-speed production environments

- Extremely thick hardwood slabs

Again — context matters.

Shop Planning Guide (Before You Buy)

Ask yourself:

- Where will this mount?

- Do I have structural support?

- How will I manage dust?

- What power do I have available?

- Where will my computer live?

- Do I have safe sheet handling space?

Think through workflow before purchasing.

That prevents regret.

Setup & First Month Reality

If you buy this machine, your first month will likely look like:

Week 1: Frame build

Week 2: Calibration

Week 3: Test cuts

Week 4: Adjustments

Don’t expect production-level results on day one.

Expect learning.

That mindset shift changes everything.

Comparing MakerMade to Other CNC Paths

Versus Benchtop CNC (2×2, 2×4)

Benchtop wins:

- Simplicity

- Ease of setup

- Smaller projects

MakerMade wins:

- Full sheet capability

- Growth potential

Versus Industrial 4×8 CNC

Industrial wins:

- Speed

- Precision

- Plug-and-play reliability

MakerMade wins:

- Cost

- Space efficiency

- Accessibility

Different classes entirely.

The Big Question: Would I Recommend It?

If you:

- Have limited space

- Want big-sheet capability

- Enjoy learning machines

- Understand tradeoffs

Yes — it deserves serious consideration.

If you:

- Want effortless production

- Need industrial speed

- Hate troubleshooting

Probably not your best match.

The Community Question (Engagement Section)

If you run a vertical CNC:

- Would you buy it again?

- What surprised you?

- What frustrated you?

- What did you wish you knew?

Drop a comment and help the next person make a smarter decision.

Final Thoughts

This machine exists in a very specific lane.

It’s not trying to be a commercial cabinet shop monster.

It’s trying to give serious makers an accessible path into 4×8 work.

And for many shops — especially garage-based businesses — that’s a powerful thing.

If you want to explore it further:

👉 https://laticy.com/CNC/Makermade